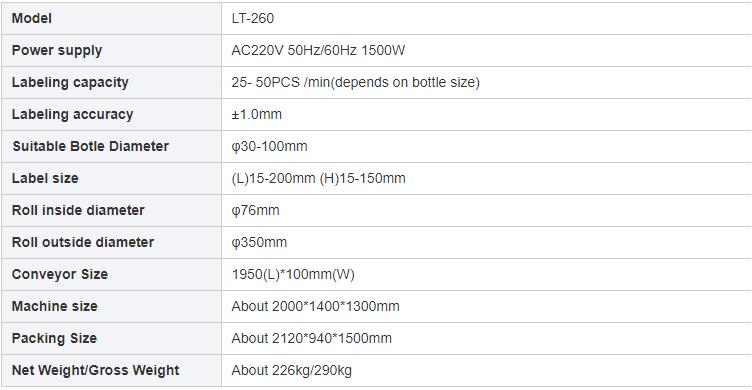

Model:LT-260

Power supply:AC220V 50Hz/60Hz 1500W

Labeling capacity:25- 50PCS /min

Labeling accuracy:±1.0mm

Suitable Botle Diameter:φ30-100mm

Label size:(L)15-200mm (H)15-150mm

Roll inside diameter:φ76mm

Roll outside diameter:φ350mm

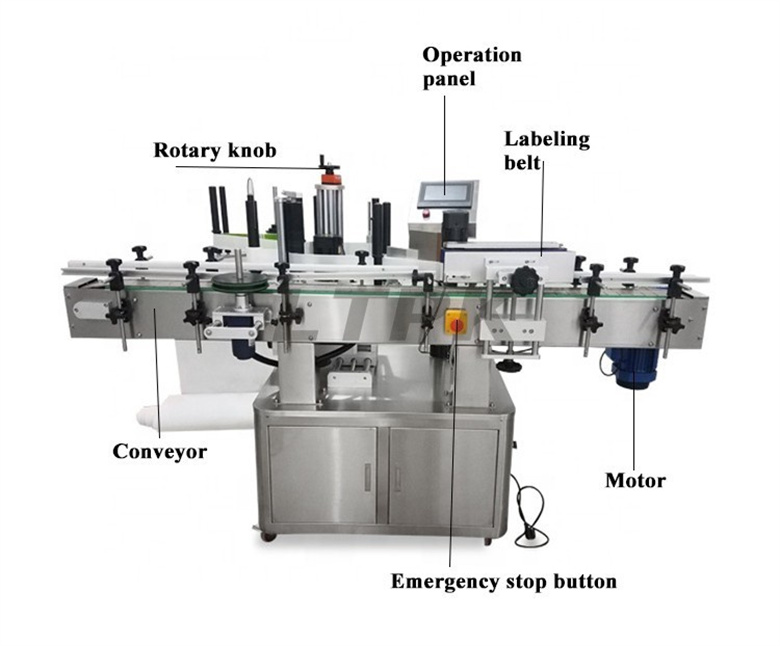

LT-260 round bottle automatic labeling machine positioning labeling machine full automatic labeling machine.

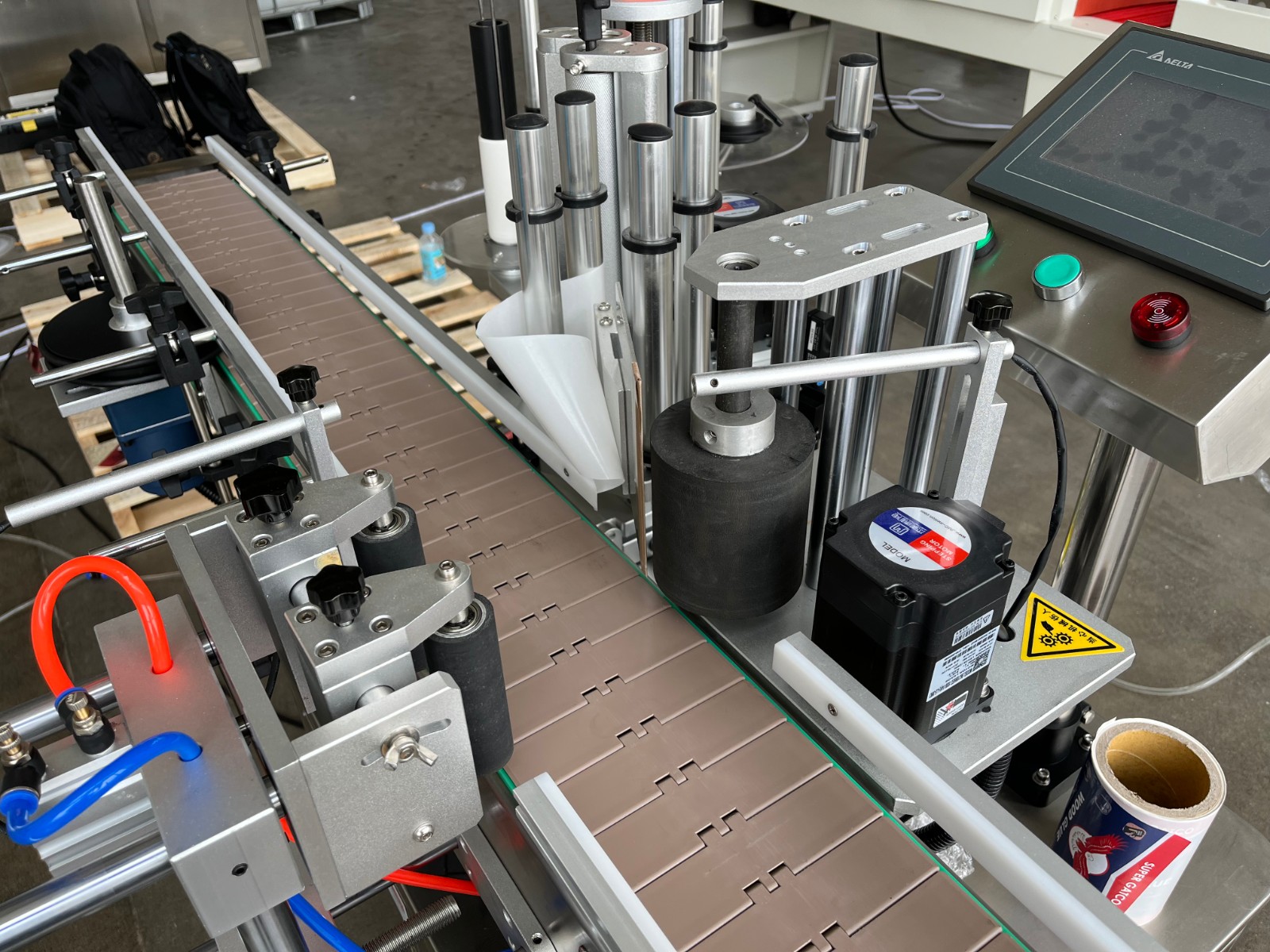

1.Make sure the bottle sensor and label sensor are working.

2.Adjust the bottle label speed, roller speed, conveyor speed to a rather medium speed. Labeling speed is adjusted on the touchscreen, the other two are adjusted by physical knobs.

3.Set the Selection time delay properly by observing how long the bottle takes get to the rolling station after it’s detected, usually it’s around 0.5 second. This setting influenced by the conveyor speed, if the conveyor speed is very slow, this will be longer.

4.Next is the Out of the delay, usually this delay time is a little bit ahead of the Selection time delay, because you want the label to just start dispensing before the clamping action is nearly complete.

5.Then the Scaling time, this is how much time the roller will be rolling on the bottle, it’s always greater than the Out of delay, otherwise you will find when the roller is rolling with no label coming out. If the bottle takes 1 second to finish labeling and rolling, and the Out of delay is 0.5 second, then for the best efficiency, this one will be 1.5 second.

6.The Delay stop mark, this is usually set to 0.5 second, if you find it sticks out too much and create wrinkle on the bottle,then you should decrease it.

7.Finally, Time interval between, make sure to change Scaling time if you set this one other than 0.

8.The Scaling time is usually doubled if you want to stick two labels on.

Parameters of machine

Application of machine

More details of machine

Contact: Debbie Zhou

Phone: 008619168267265

E-mail: debbiezhou@packmachinefactory.com

Whatsapp:+8619168267265

Add: NORTH OF .408-1 XIAJIN ROAD, SOUTH BAIXIANG STREET, OUHAI DISTRICT ,WENZHOU

We chat